Decentralized supply chains and distributed manufacturing are two concepts that are reshaping the way goods are produced and delivered in the 21st century. In this blog post, I will explain what these terms mean, how they differ from traditional supply chains and manufacturing models, and how they will impact the future of businesses and consumers. I will also explore the possibility of achieving a star trek replicator-like technology that can create anything on demand.

A supply chain is the network of activities, people, resources, and information that are involved in moving a product or service from the supplier to the customer. A traditional supply chain is centralized, meaning that it relies on a few large entities that control the production and distribution of goods. For example, a car manufacturer may source its raw materials from a few suppliers, assemble them in a few factories, and distribute them to a few dealerships.

A decentralized supply chain is one that is distributed among many smaller entities that collaborate and coordinate their actions through digital platforms. For example, a car manufacturer may source its raw materials from a network of local suppliers, assemble them in a network of micro-factories, and distribute them to a network of customers or service providers. A decentralized supply chain can offer several benefits, such as:

- Increased efficiency and resilience: By reducing the distance and intermediaries between the source and the destination of goods, a decentralized supply chain can lower the costs and risks of transportation, storage, and inventory. It can also increase the flexibility and responsiveness to changing customer demands and market conditions.

- Increased innovation and customization: By enabling more participation and collaboration among different actors in the supply chain, a decentralized supply chain can foster more creativity and diversity in product design and development. It can also allow more personalization and differentiation of products and services to meet customer preferences and needs.

- Increased sustainability and social impact: By reducing the environmental footprint and waste of production and distribution, a decentralized supply chain can contribute to more sustainable development goals. It can also empower local communities and workers by creating more opportunities for income generation and skill development.

A manufacturing model is the way goods are produced using various technologies and processes. A traditional manufacturing model is centralized, meaning that it relies on large-scale factories that use mass production techniques to produce standardized goods. For example, a clothing manufacturer may use automated machines to cut, sew, and print thousands of identical garments.

A distributed manufacturing model is one that is decentralized, meaning that it relies on small-scale facilities that use digital fabrication techniques to produce customized goods. For example, a clothing manufacturer may use 3D printers or laser cutters to create unique garments on demand. A distributed manufacturing model can offer several benefits, such as:

- Reduced costs and waste: By producing goods only when they are needed and where they are needed, a distributed manufacturing model can eliminate the need for excess inventory and storage. It can also reduce the material and energy consumption of production.

- Enhanced quality and performance: By using advanced technologies and processes that can create complex shapes and structures, a distributed manufacturing model can improve the functionality and durability of goods. It can also enable more testing and feedback loops to ensure quality standards.

- Expanded creativity and diversity: By allowing more access and control over the design and production of goods, a distributed manufacturing model can unleash more potential for innovation and expression. It can also cater to more niche markets and segments that are underserved by mass production.

Decentralized supply chains and distributed manufacturing are not mutually exclusive concepts. In fact, they can complement each other to create a more integrated and agile system of production and delivery. For example, a decentralized supply chain can leverage distributed manufacturing to produce goods closer to the customers or end-users, while distributed manufacturing can leverage decentralized supply chains to source materials or components from local or regional suppliers.

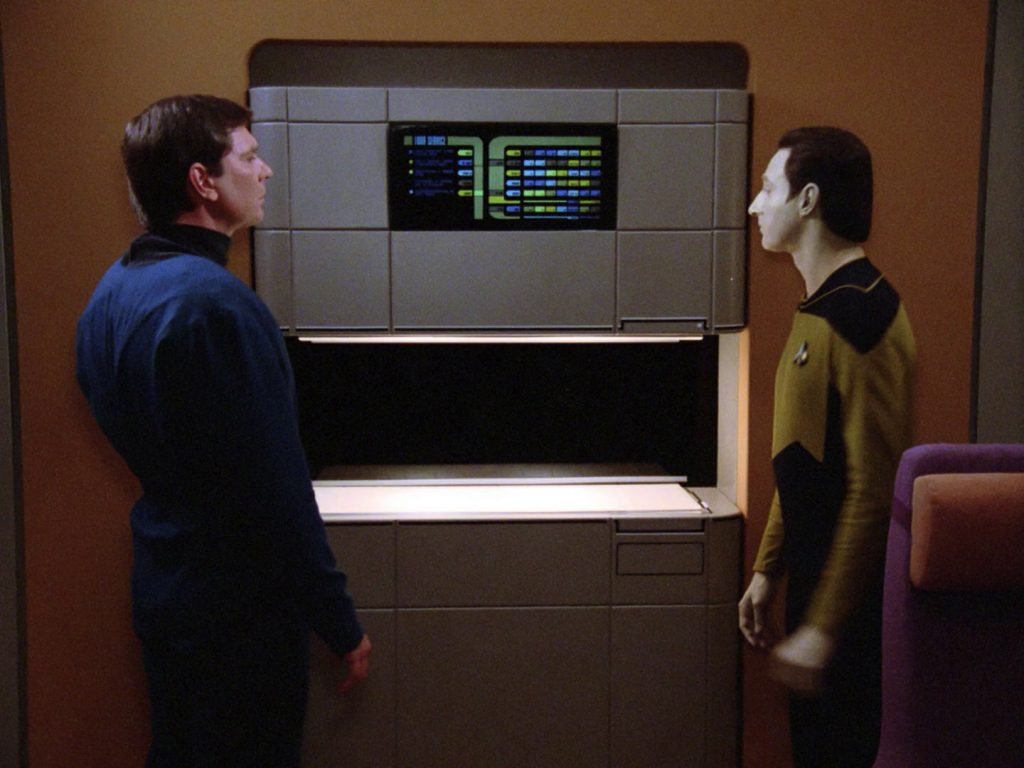

The ultimate vision of decentralized supply chains and distributed manufacturing is to achieve a star trek replicator-like technology that can create anything on demand. A star trek replicator is a fictional device that can materialize any object or substance by rearranging subatomic particles. Such a technology would revolutionize the way we consume goods and services by eliminating the need for any physical transportation or storage. It would also enable us to create anything we want or need with minimal resources or constraints.